-

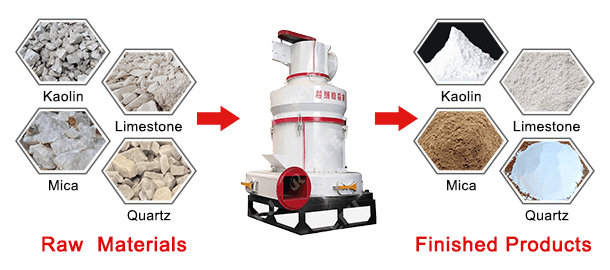

Applicable materialsCalcium carbonate, coal, limestone, quartzite, barite, calcite, kaolin, gypsum, pyrophyllite, petroleum coke, etc.

-

Feed size≤30mm

Applicable Material

Ore type:

Heavy calcium carbonate: limestone, calcite, marble, dolomite, etc.Barite, potassium feldspar, albite, talc, fluorite, mullite, paraffin, sepiolite, manganese ore, copper ore, iron ore, molybdenum ore, antimony ore, marquise, calcite , Quartz stone, volcanic stone, malachite, harzburgite, weathered stone, aluminum ore, zircon stone, quartz sand, vein ore, mica stone, tin ore, scheelite, diabase, ilmenite, sandy tin Mine, gangue, magnesium ore, medical stone, phosphate rock, shale, silica, wollastonite, brucite, hydrated lime, mullite, paraffin stone

Minerals:

Bauxite, bentonite, kaolin, white clay, loess, clay, gypsum, graphite, cement, double fly powder, white powder, titanium dioxide, pottery clay, porcelain clay, magnesium iron oxide, chromium oxide green, attapulgite, barium salt, glass, thermal insulation

Material:

Solid fuel pulverization:Lignite, humic acid, blast furnace coal injection, petroleum coke, carbon blocks, carbon, etc.

Special categories:Activated carbon, pig iron pins, cassava, tungsten bars, coconut shells, charcoal, chemical raw materials, shellfish, etc.Power plant desulfurization limestone powder making;

Slag micron powder processing;Grinding projects in building materials, chemical industry, metallurgy and other industries.

Product Features

High grinding efficiency and convenient fineness adjustment

It is capable of continuous production, large production capacity, high grinding efficiency, multiple sorting heads, uniform fineness of finished products, easy to adjust fineness, and small energy loss.Strong adaptability

Strong adaptability to materials, can grind a variety of hardness of non-metallic ores.Finished product grading, one machine as two machines

The analyzers of the mill are used with multiple heads, and the fineness of the separating materials is uniform and controllable. The classifier can produce fine powder with more than 2500 mesh.Fewer transmission parts, low maintenance costs

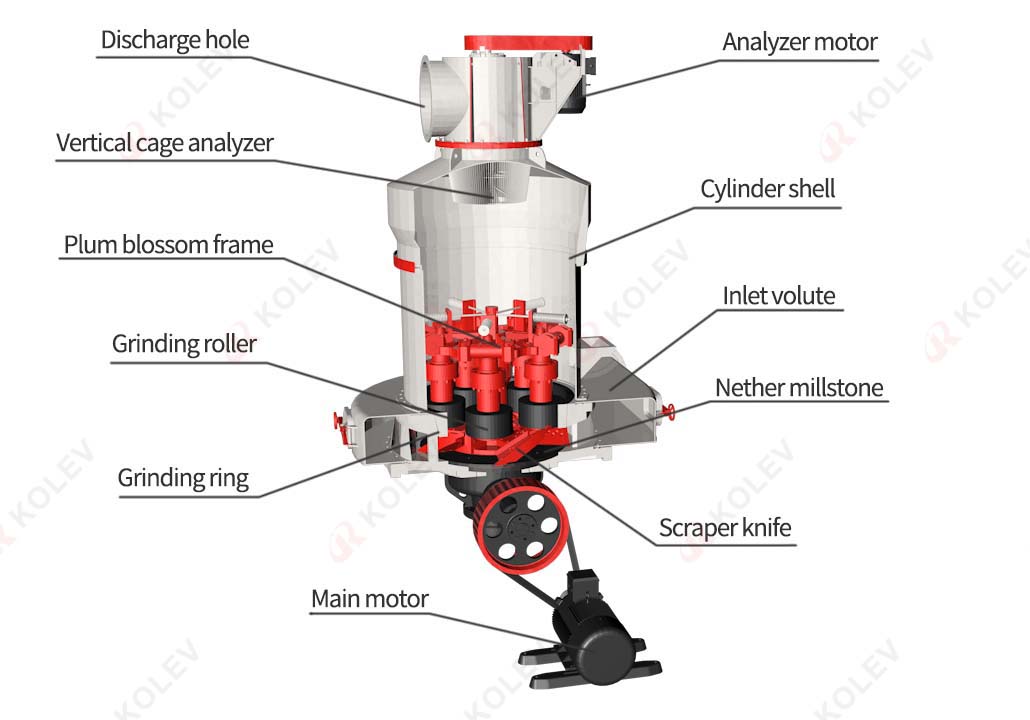

The equipment has compact structure, less transmission parts, low maintenance cost, stable operation and easy installation.Working Principle

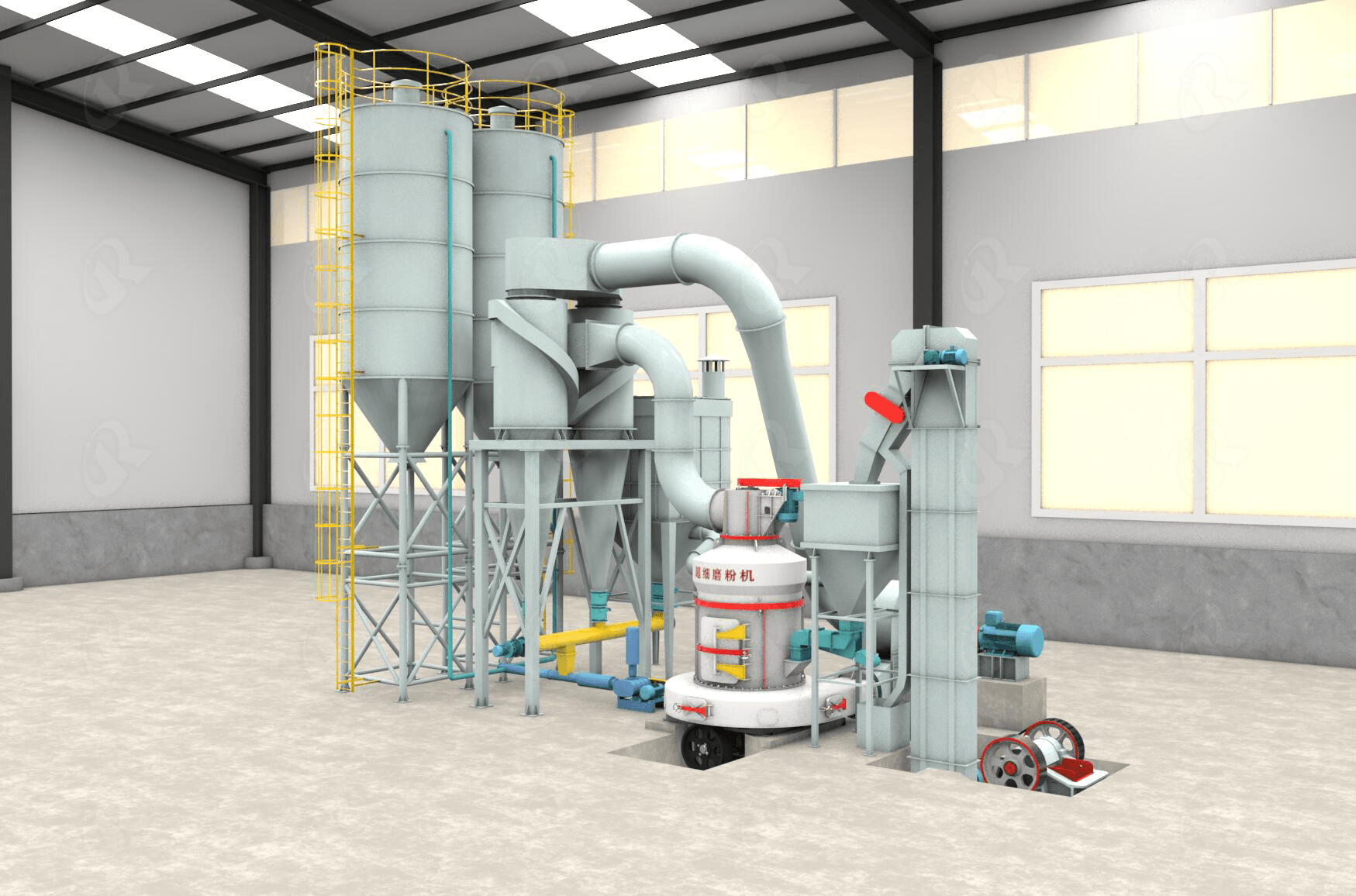

- KL ultrafine grinding mill workflow,After big block be crushed into small particle by the jaw crusher.

2.Fall into the transfer bin through the bucket elevator,The electric magnetic vibrating feeder under transfer bin evenly feed the material into the ultrafine grinding mill to grinding according to the set quantity of flow.

3.The high speed rotation impeller of the ultrafine grinding mill will separate the powder, the unqualified material will fall into bottom to grinding again.

4.The qualified material go into the powder collector with the airflow,then transport to the discharge hole by the discharge screw, the excess air suction into dust remover by the negative pressure fan and discharge after reach the standard of the dust remove.

5.The dust transport to the discharge hole by the bottom discharge screw.

Technical Parameter

| Model | KL1120 | KL1450 | KL1760 | KL1950 | KL2100 |

| Handling Ability (t/h) | 2-6 | 5-10 | 8-20 | 15-30 | 20-40 |

| Main Motor Power(kw) | 45 | 90 | 132 | 185 | 220 |

| Fan power(kw) | 37 | 90 | 132 | 185 | 220 |

| Analyst power(kw) | 5.5 | 7.5 | 22 | 37 | 45 |

| Rotate Speed(r/m) | 120 | 90 | 90 | 90 | 90 |

| Diameter of Grinding Ring(mm) | 1100 | 1450 | 1760 | 1950 | 2100 |

| Diameter of Grinding Roll(mm) | 320 | 400 | 450 | 570 | 630 |

| Maximum Feed(mm) | 25 | 30 | 30 | 40 | 40 |

| Finished Particle Size(mm/mesh) |

1.6------0.023mm(16-600mesh) |

||||

| Weight(t) | 14.5 | 26 | 48 | 65 | 85 |

Company Profile

Kolev Equipment Technology Co., Ltd. is a large-scale private technology enterprise. The company is committed to the research and development, production and sales of technical equipment for the mining and metal ore industries. It has been deeply involved in the ultra-fine grinding, industrial drying and crushing sand making industries for many years. We can provide you with Provide intelligent solutions and mature supporting products, focusing on the development of various powder equipment, complete powder production lines, drying production lines, sand and gravel line equipment and projects.Products are sold to 160 countries and regions and are well received by customers.

Kolev Equipment has always been adhering to the business philosophy of surviving by quality and developing by credibility, striving to win the trust of customers with high-quality products and perfect after-sales service, and create a brilliant future for Kolev.

+86 166-3801-7614

+86 166-3801-7614