-

Applicable materialsCalcite, coal, chalk, kaolin, carbon black, bentonite, talc, limestone, dolomite, mica, etc.

-

Capacity0.5-12t/h

-

Maximum feed size≤20 mm

-

Output fineness5-100μm(Adjustable)

Applicable Material

Three Ring Medium Speed Micro Grinding Mill is suitable for the super fine grinding of all kinds of crisp materials whose Moh’s hardness is below 7, such as calcium carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, white mud, mica, refractory material, glass.

Product Features

Low investment cost

At the same fineness, it has less input, lower cost and shorter recovery cycle than air grinding.Long service life

In the case of the same fineness of materials and finished products, the service life is longer than that of ordinary grinding mill equipment wear parts, generally up to more than 1 year.Energy saving and environmental protection

The crushing and grading of materials to finished products are carried out in a closed system. The dust-containing gas is treated by dust removal, and there is no pollution. It is an ideal equipment for green environmental protection.Work safety and reliability

There is no rolling bearing or screw in the grinding chamber. There is no bearing and its sealing parts easy to damage and screw loose and damage the machine.Working Principle

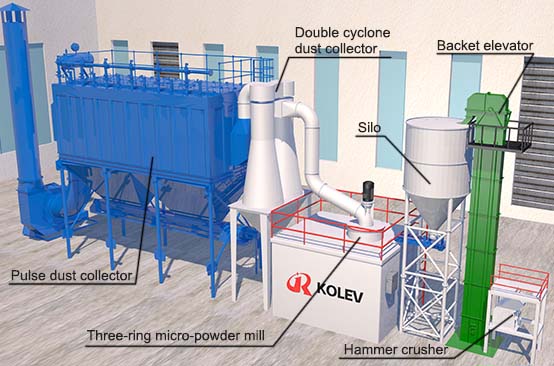

1.The motor of Three Ring Medium Speed Micro Grinding Mill drives the spindle and the turntable of each layer to rotate through the reducer, and the turntable drives dozens of ring rollers to roll and rotate in the raceway of the grinding ring through the pin.

2.The bulk material is broken into small particles by the crusher and sent to the storage bin by the bucket elevator. The screw feeder evenly sends the material to the middle of the upper rotary table.

3.The material is scattered to the periphery of the circle under the action of centrifugal force, and falls into the raceway of the grinding ring by the ring roller punching, rolling, grinding and crushing. The suction effect of the high pressure centrifugal fan will draw the external air into the machine, and the coarse powder after the third layer of grinding will be brought into the separator.

4.The snail flow generated by the rotating worm gear in the classifier makes the coarse particle material fall back to the re-grinding, and the fine powder enters double cyclone dust collector with the air flow and is discharged by the discharge valve at its lower part, which is the finished product.

5.The air flow with a small amount of fine dust is purified by the pulse dust collector and discharged from dischagrge hole.

Technical Parameter

| Model | mean diameter(mm) | Number of loops( pcs ) | Feed size(mm) | Size range of finished product(mesh) | Finished product output(t/h) | boundary dimension(L*W*H)(mm) | main motor power(KW) | Power of separator(KW) |

| KLM800 | 800 | 3 | ≤10 | 150-3000 | 0.5-6 | 8605*4139x6050 | 75 | 15 |

| KLM800B | 800 | 3 | ≤10 | 150-3000 | 0.5-6 | 10454*3393*6626 | 75 | 5.5*3 |

| KLM1000 | 1000 | 4 | ≤15 | 150-3000 | 1.2-10.5 | 14507*3633*7562 | 132 | 22 |

| KLM1000B | 1000 | 4 | ≤15 | 150-3000 | 1.2-11.5 | 14362*4200*7562 | 132 | 5.5*3 |

| KLM1250 | 1250 | 4 | ≤20 | 150-2000 | 2.5-20.5 | 19261*4406*8591 | 185 | 37 |

| KLM1250B | 1250 | 4 | ≤20 | 150-3000 | 2.5-20 | 25067*5414*9007 | 185 | 5.5*4 |

| The device parameters are based on actual devices | Only main engine and dust collector system|Other options | |||||||

Company Profile

Kolev Equipment Technology Co., Ltd. is a large-scale private technology enterprise. The company is committed to the research and development, production and sales of technical equipment for the mining and metal ore industries. It has been deeply involved in the ultra-fine grinding, industrial drying and crushing sand making industries for many years. We can provide you with Provide intelligent solutions and mature supporting products, focusing on the development of various powder equipment, complete powder production lines, drying production lines, sand and gravel line equipment and projects.Products are sold to 160 countries and regions and are well received by customers.

Kolev Equipment has always been adhering to the business philosophy of surviving by quality and developing by credibility, striving to win the trust of customers with high-quality products and perfect after-sales service, and create a brilliant future for Kolev.

+86 166-3801-7614

+86 166-3801-7614