-

Dispose of materialssilica sand,Quartz ,Ore , Clay

-

Feeding Size5mm

-

Output size0.045-0.023mm

-

Capacity1.5-25T/H

Introduction

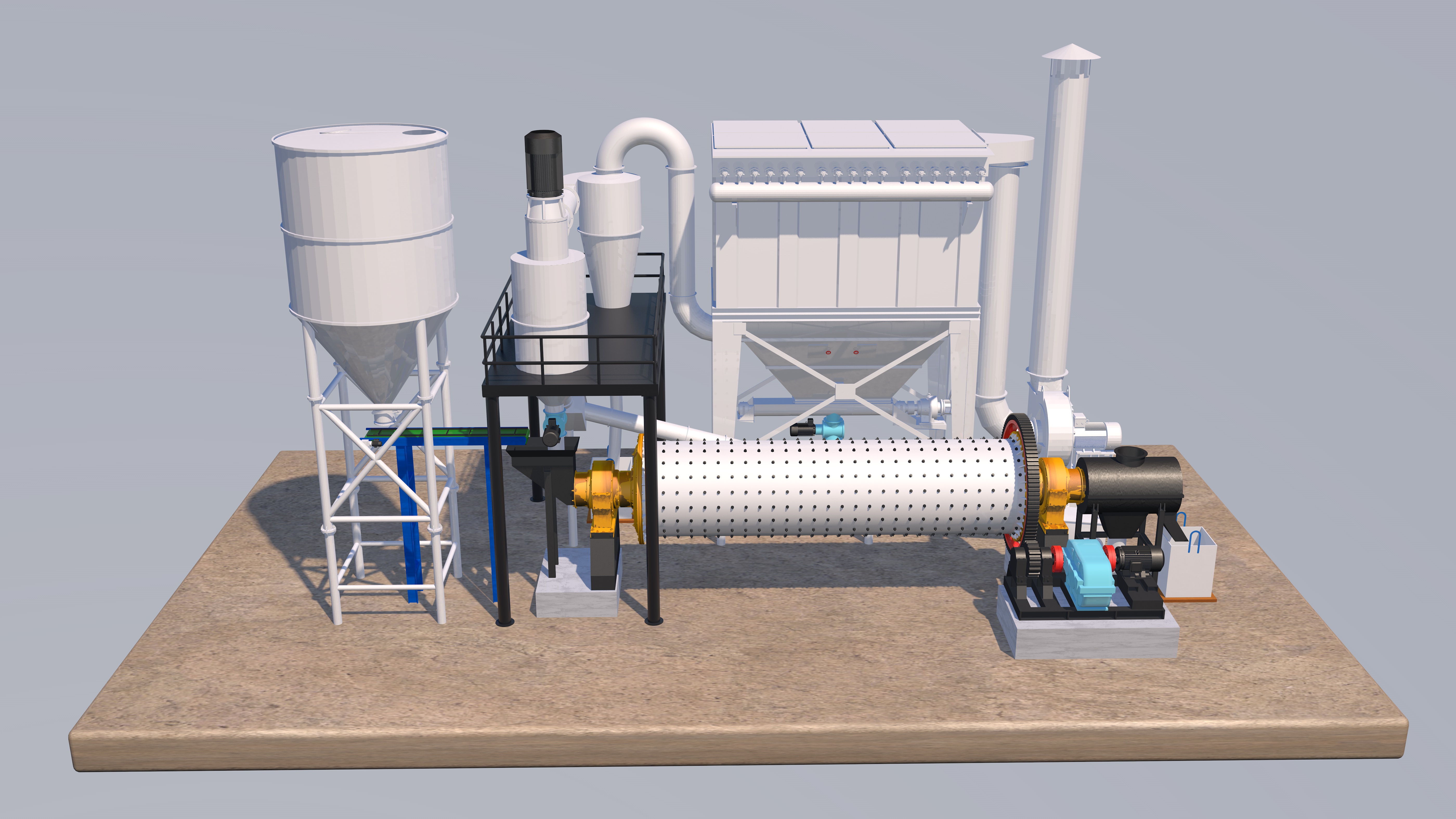

Silica sand powder is commonly used in photovoltaic and glass industries. Due to its special properties, low iron impurities are required and ceramic ball mills are required.

The ceramic ball mill produced by our company is a high-fine grinding machine. The material should be fed into the mill in a medium-fine state to achieve grinding efficiency. The interior adopts ceramic liners and ceramic balls, and the feed and discharge ends are made of stainless steel, which has excellent wear resistance and chemical stability and is not easy to contaminate materials. The ceramic ball mill is mainly used for mixing and grinding materials. The fineness of the product is uniform and energy-saving. It can be dry-milled or wet-milled. The ceramic ball mill can use different liner types according to production needs to meet different needs. The fineness of the grinding operation is controlled by the grinding time.

Product Features

Simple structure, smooth operation

There is no inertia impact, the equipment runs smoothly, and reduces the downtime and maintenance time of the mill, improving the efficiency.Particle size ratio is good

The product fineness (particle size ratio) is uniform and the quality is stableClosed system is adopted to reduce dust

Ball mill and classifier form closed system, negative pressure conveying, small dust, green environment protection.Reliable operation, energy saving effect is remarkable

The bearing body is lubricated by grease, which greatly reduces friction resistance, and the fuel consumption is extremely low and the operation is more convenient.Working Principle

The silica sand ball mill is mainly composed of a grinding jar, a ceramic ball mill, a transmission mechanism and a control system. When the machine is started, the motor drives the transmission mechanism to rotate the grinding jar, causing the ceramic ball in the jar to rotate. During the rotation, the material is driven to the grinding area in the jar, and is continuously ground, mixed and dispersed under the friction and impact of the ceramic ball. The appropriate finished product is screened out by the powder selector, and the unqualified ones will continue to be ground. This grinding solution uses a closed-flow grinding device.

Technical Parameter

| Model | Processing Capacity | Speed | Powder | Machine Weight |

| φ1200×4500 | 1.5-2.0 | 32 | 55 | 12.8 |

| φ1500×5700 | 3.0-4.0 | 27 | 130 | 23.5 |

| φ1830×4500 | 5.0-6.0 | 26 | 185 | 28.0 |

| φ1830×7500 | 6.0-8.0 | 26.5 | 210 | 36 |

| φ2100×4500 | 8.0-10 | 26 | 210 | 42 |

| φ2100×9000 | 10-12 | 24 | 280 | 48 |

| φ2200×7000 | 10-12 | 23.5 | 280 | 50 |

| φ2200×9000 | 12-15 | 23.5 | 380 | 65 |

| φ2400×9000 | 15-18 | 21 | 475 | 75 |

| φ2700×4500 | 18-20 | 21 | 475 | 75 |

| φ2700×9000 | 20-25 | 20.5 | 630 | 108 |

+86 166-3801-7614

+86 166-3801-7614