-

Output size350-2000 mesh

-

Capacity0.5-20 t/h

-

Power18.5kw-1000kw

Applicable Material

Product Features

Simple structure, smooth operation

There is no inertia impact, the equipment runs smoothly, and reduces the downtime and maintenance time of the mill, improving the efficiency.Parts wear resistant, long life

Using high quality plate, lining can be replaced, rotary gear using casting gear hobbing processing, the cylinder body is inlaid with wear-resistant lining plate, has good wear resistance.Closed system is adopted to reduce dust

Ball mill and classifier form closed system, negative pressure conveying, small dust, green environment protection.Reliable operation, energy saving effect is remarkable

The bearing body is lubricated by grease, which greatly reduces friction resistance, and the fuel consumption is extremely low and the operation is more convenient.Working Principle

1.Ceramic ball mill is a omitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber.

2.The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Technical Parameter

|

Model

|

Cylinder rotational speed (r/min)

|

Feeding size(mm)

|

Discharging size(um)

|

Capacity (t/h)

|

Power (KW)

|

|

1200×4500

|

32 |

≤20

|

150-5

|

1.5-2

|

55

|

|

1500×5700

|

27

|

≤20

|

150-5

|

2.5-5

|

130

|

|

1830x4500

|

26

|

≤25

|

150-5 |

3-6

|

185

|

|

1830x7000

|

26.5

|

≤25

|

150-5 |

4-8

|

210

|

|

2100x4500

|

26

|

≤25

|

150-5 |

5-10

|

210

|

|

2100x9000

|

24

|

≤25

|

150-5 |

5-12

|

280

|

|

2200x7000

|

23.5

|

≤25

|

150-5 |

6-12

|

380

|

|

2200x9000

|

23.5

|

≤25

|

150-5 |

6-15

|

380

|

|

2400x9000

|

21

|

≤25

|

150-5 |

8-20

|

475

|

|

2700x9000

|

21

|

≤25

|

150-5 |

9-20

|

475

|

|

2700x11000

|

20.5

|

≤25

|

150-5 |

10-25

|

560

|

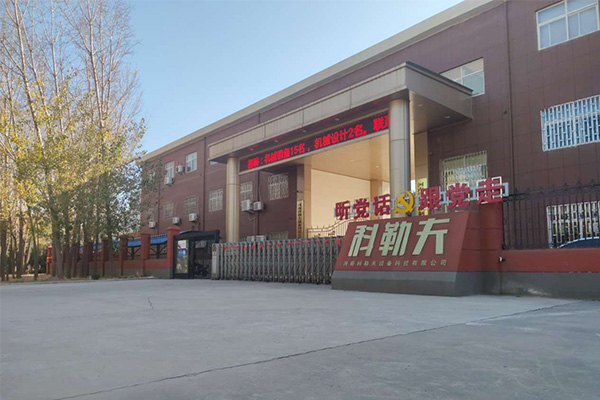

Company Profile

Kolev Equipment Technology Co., Ltd. is a large-scale private technology enterprise. The company is committed to the research and development, production and sales of technical equipment for the mining and metal ore industries. It has been deeply involved in the ultra-fine grinding, industrial drying and crushing sand making industries for many years. We can provide you with Provide intelligent solutions and mature supporting products, focusing on the development of various powder equipment, complete powder production lines, drying production lines, sand and gravel line equipment and projects.Products are sold to 160 countries and regions and are well received by customers.

Kolev Equipment has always been adhering to the business philosophy of surviving by quality and developing by credibility, striving to win the trust of customers with high-quality products and perfect after-sales service, and create a brilliant future for Kolev.

+86 166-3801-7614

+86 166-3801-7614