Conduct on-site testing, tailor design, provide solutions, and optimize resource allocation

Direct supply from stock, eliminating intermediate channels, and providing a complete set of pre-sales, in sales, and after-sales services

The customer grinds quartz to make glass, semiconductor chip packaging materials, solar cells, LCD display screens and other materials. There are requirements for the iron content of the material. We use ceramic ball mills as grinding equipment according to customer requirements, and the quartz conveying equipment and screening equipment are made of stainless steel.

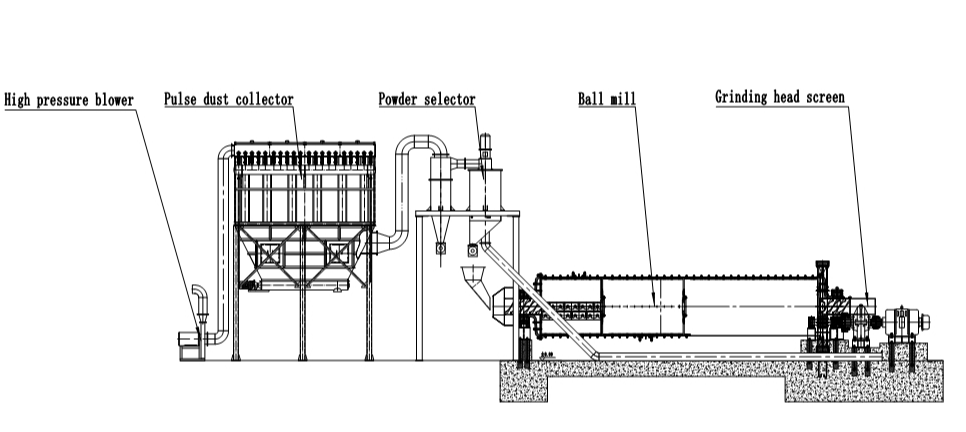

The production line is mainly composed of a swing screen, a quartz mill, a powder selector, and a pulse dust collector

Quartz mill (ceramic ball mill)

The interior uses ceramic liners and ceramic balls, and the feed and discharge ends are made of stainless steel. It has excellent wear resistance and chemical stability and is not easy to contaminate materials. Ceramic ball mills are mainly used for mixing and grinding materials. The product fineness is uniform and energy-saving. It can be dry or wet. Ceramic ball mills can use different liner types according to production needs to meet different needs. The fineness of the grinding operation is controlled by the grinding time.